Staying with OHVs makes good business sense for GM because the designs and tooling are mature. The enthusiast community, and the automotive press both tend to be hard on the low-end pushrod engines, describing them as "buzzy" and "low tech". However, does the average consumer care? Does your father-in-law the pediatrician know if he has an OHV or DOHC engine in his car? Does your mother-in-law know? If someone is buying a car as an appliance, they may not even care if they are buying an I4 or a V6 (see: Toyota Camry). Many people just want a reliable car at a good price, and won't care about a pushrod design. Some of them might even enjoy the throaty roar.

GM's pushrods are not all primitive, and are getting more advanced, picking up many of the high-tech features. Cylinder de-activation is relatively simple and cheap with the OHV architecture--bleed oil pressure from valve lifters using a solenoid valve. Cylinder deactivation on a OHC design requires some complicated mechanics and electronics, such as BMW's throttle-less Valvetronic engine. The added complexity adds cost and reduces reliability. (Anyone seen a valve de-activation system from Ford yet?)

BMW's Valvetronic valvetrain, courtesy of bmwworld.com

In a recent issue of Automotive Engineering, SAE's monthly glossy, there were some diagrams of a new GM engine design. It has a single cam OHV system which adds a 3rd valve per cylinder by using a horizontal pushrod, which connects to a pivot . You can download a brochure from GM here.

Courtesy of GM.com

A few years ago GM showed the XV8 concept--a twin cam OHV engine. This design supports 3 valves per cylinder and variable cam phasing. The second cam rides over the lower cam, and is driven by a slave chain.

GM's XV8 engine, courtesy of Carcraft.com

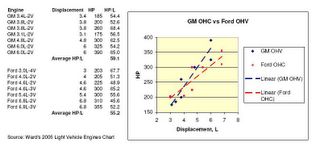

GM squeezes some pretty good torque and fuel economy numbers from their engines. Nothing wrong with that. Here is a chart I threw together that shows the distribution of specific power (HP/L) for GM's OHV engines, vs. a sampling of Ford's OHV engines. GM actualy does a little better, in terms of HP/L, with its OHV designs. The data came from Ward's excellent 2005 Light Vehicle Engines chart.

(click for full size version)

GM also puts electronic throttle control on its pushrods--not exactly primtive.

Other advantages: pushrod engines can be made light, like OHCs, using aluminum and magnesium. Pushrod engines don't need long timing belts or chains. They are not as tall as OHC designs, allowing for a lower center of mass, or a more wedge shaped vehicle profile.

The 300C with HEMI is a pushrod, and it is the media darling. And I don't hear many people howling about the Corvette having a pushrod engine.

51 comments:

FWIW - GM's official blog has added a link to your comment about pushrod engines. I completely agree with your comments about harshness - the engines don't sound anywhere near as bad as the auto magazine writers make it out to be - and anyway, this harshness starts at maybe a little below 4000 rpm. I don't think the average driver will rev his engine that high very often.

But then, the average driver doesn't care what enthusiast magazines say. He probably looks at the "consumer" magazines - which treat all cars as appliances.

- HCE

I like the pushrod engines over OHC because many OHC engines produce a lot of high end power (my car maxes out at 260@5800 RPM). I hate running an engine that high, and I rarely get anywhere near that in daily driving.

Low-end torque is what gets the job done most of the time. High RPM power is great once you have spun up the engine, but if it takes a long time to do it, you don't have much fun.

The only problem with pushrods is the lack of "whirly-bits" factor. Lots of folks will rattle off all the specs of their VTEC Honda, but really don't have the foggiest idea what it all means.

I had a pushrod 3.3 Dodge Intrepid that turned every bit as good gas mileage any Accord V6. All done without whirly-bits.

The problem is: folks become convinced they need the whirly-bits or they are missing out.

The Friendly Grizzly

I completely agree with your statements. I often get frustrated with the pious automotive press whining about pushrod technology. I can tell you just from the people that I know, 99% of them know how many cylinders they have in their car (although many of them probably aren't real clear on what a "cylinder" is), and what their gas mileage is. That is about as deep as they get into their engine technology. Period.

- Don

I'm with you on this one. There really isn't a huge improvement to be had from OHC like there might have been 15-20 years ago, mostly because of engine control electronics. I think the reason OHV gets such a bad rap from the automotive press is because of their negative bias towards domestic producers. It's been said before, most people don't know/care what actuates their valvetrain, just as long as the damned thing starts up in the morning. The one thing I think you may have not stated is oiling (the cam and lifters) is much easier, because the oil doesn't have to travel as far. Maybe because this applies to older/less well maintained engines. You can abuse a pushrod engine far more than an OHC for sure. (Ask me how I know...) Thanks for your time.

geozinger

I agree with you, the pushrod has a lot of life left in it. I think certain car magazines get so wrapped up in talking about every cars new features that if another car doesn't have it, it must be a negative bullet point. The fact is, the pushrod is time tested, simple, and very reliable. Automagazines would never want you to know that the 1930 Duesenberg had an overhead cam engine, so they aren't exactly new or amazing. The old adage is still true today: horsepower sells cars but torque moves it down the road/track. Everytime I hear a snooty european car owner talk about how great the new M5 engine is I have to chuckle to myself. Sure it makes 500hp, AT 8000 RPM. Even when an engine is designed to run at redline + WOT, it still has moving parts, and moving parts don't like high rpms. Plus, with all horsepower at high RPM cars, you will rarely get to all the horsepower you bought since it has to wind up so far. One of my cars is a Toyota Celica, and I love that thing. It has a 7600 redline, and I think during normal driving I go past 5000 maybe once a month during particularly hairy freeway merges. Sure it makes 180hp out of 1.8 liters, but I rarely get to enjoy all of it. I see hondas with similar redlines riced out driving around all the time. I can tell they enjoy their high rpm power a lot by the amount of blueish smoke coming out of their tailpipe =)

Excellent post.

Something to keep in mind is that powerband has little to do with where the camshafts are placed in the block. Go take a ride in a Mustang 5.0 with big heads and a monster solid-roller cam sometime. Heck, even the 396 stroker in my Impala has a preference for higher revs, with a definite step in the powerband at about 3,000 RPM. Powerband is a matter of displacement, head flow, camshaft timing, and many other factors, but the air that's moving through the head doesn't know how the valves got opened.

As the 505 HP LS7 shows, pushrod motors are still plenty viable for performance applications. It produces over 350 ft-lb of torque from 1000 to 7000 RPM. And the Z06 that it's installed in looks to be the only 500+ HP car that doesn't carry the gas-guzzler tax.

Pushrods are here to stay,but rotory motors have stood the test of time too. I assume that there is allways research for a more effecient motor in fuel miliage as well as dezign. Keep a open mind and who knows what the future holds.

Pushrod OHV designs will certainly move a car effectively from points A to B, but GM isn't operating in a vacuum. It's up against the super-smoothies inhabiting the engine bay of every Toyota, Honda, BMW -- practically every other manufacturer. In the contest of pleasant underhood sensations, the General's pushrods lose badly. It's a matter of perception, and GM desperately needs every ounce of help it can get in that realm.

I do not understand the criticism of the sound of overhead valve engines. The 5.7 liter in my Chevrolet Camaro Z28 SS sounds much better than the overhead cam engines in the four Hondas I have purchased new, 2 Civic EX’s and 2 Accord EX’s. I don’t equate the metallic and whiney sounds the Honda engines emit under acceleration with high quality. Can anyone explain to me why the typical auto journalist thinks GM overhead valve engines sound bad and Honda VTEC overhead cam engines sound good?

Respectfully,

Eric M. Vest

The pushrod problem isn't with GM's wonderful GenIII/IV OHV V8s. Instead, it's with their outdated V6 lineup. As much as I admire the durability of the 3800 (intake gasket failures notwithstanding), it's just a coarse and unsatisfying engine. With the new 3.5 and 3.9 L V6s, I expect much of that to change for the better, but I think the damage to GM's reputation has already been done. I think these new engines might be five years too late.

Quit knocking the GM 3800! I have had 4 of them, and love them. Put over 155K miles on my 89 Lesabre and then donated it. My '02 Lesabre with GS option is hotter than my old 67 Mustang, 4 barrels and 10:1 compression included. Also it gets 31+ MPG on the highway and overall 26.4 MPG from day one.

Bob H.

Quit knocking the GM 3800! I have had 4 of them, and love them. Put over 155K miles on my 89 Lesabre and then donated it. My '02 Lesabre with GS option is hotter than my old 67 Mustang, 4 barrels and 10:1 compression included. Also it gets 31+ MPG on the highway and overall 26.4 MPG from day one.

Bob H.

I've owned 2 GM cars with base pushrod engines, a Grand Prix with a 3.1 liter V6 and a Bonneville with a 3.8 liter V6. I enjoyed driving both car as they had good throttle response and torque. I was also comforted by the fact that these engines were very simple in design (less to go wrong). I now own a Dodge with a high-revving 2.7 liter OHC engine. For all it's technical advances, this engine relies on horsepower generated at high RPM's to get you down the road. Now I worry about the fact that I'm constantly spinning an extra cam, a mile of timing chain, sprockets, tensioners, etc. well over 4000 RPM any time I need to pass a slow car or get on the freeway.

Give me back my pushrod engine and my peace of mind!

I drive a 2002 Chevy Monte Carlo SS with the well-known 3.8L pushrod V6. I love the performance of the engine. It's a nice combination of horse power, torque, and decent gas mileage. It's throaty sound adds to its appeal. The aerodynamic design of the car along with the engine performance make accelerating and high-speed cruising enjoyable. I'm partial toward older technology that's still viable, and I hope the pushrod OHV technology doesn't go away any time soon.

GM has done amazing things with the LS1/2/6/7 series of pushrod engines. I drive a vehicle with an LS6, so I have some idea :D

Ok, they don't have the HP/litre of some OHC engines. So what? Unless someone tells you that number, you'll never know.

What they DO have, is excellent HP/weight, excellent HP/size, excellent fuel economy per HP, excellent reliability, and so forth. My LS6 gets comparable fuel efficiency to some engines with barely half its HP. There are advantages to the form factor possible in pushrod engines, too, so the vehicle's center of gravity can be lowered.

I think the LS series are among the very best engines produced today by any manufacturer in normal production cars. Who cares what the technology is, if it works so well?

People seem to forget that OHC engines have been around just as long as OHV engines; they are not new technology. The LS series of engines have been awarded as some of the best engines on the market, and for good reason, GM put alot of time and effort into the LS series engines. Examples such as the LS7 just go to show you that you should never relegate proven technology to the history books just because something with more parts comes along. The same with GM and American ingenuity. I hear alot of comments on the superiority of Japanese or German engineers, and I think "GM and American engineers for that matter, can come up with anything they put their minds to. Just look at the Corvette; Over 50 years old and it's still a formidable competitor to vehicles costing three times as much."

Low-end torque is what gets the job done most of the time.

With simple modifications like http://www.somender-singh.com grooves to increase turbulence, low end torque and burn comletion, people might be a lot more inclined to use them.

The price is right and there is a lot more efficiency to be found in the pushrod.

wow did anyone count the number of comments here???

I can back this statement boldly - never before have i seen just a single modification improve torque like Singh's grooves.My first experience was in 1995 test driving a modified Suzuki 800 cc 3-cylinder car,known as the Maruti in India.This small car felt as if its engine had grown into a 1000 + cc.A/C loading was almost eliminated. over the years i have had the opportunity to test drive over 10 different later model cars modified by Singh like the Ford Ikon,Opel Astra,Hyundai Santro, Accent,Daewoo-cielo,fiat other indian cars and bikes.All of them displaying the same brute torque and instant response from a cold engine. Today i drive a 2004 model suzuki baleno1590cc SOHC,16 VALVE, mpfi-5 speed manual transmission car which was modified by Singh last December. I know my car will leave any other stock car of 1800 to 2000 cc class ( non turbo) standing in any gear through any terrain. If it comes to Fuel consumption i will run any body dry of a tank full of gas and have enough to get back home and start my day. Oils don;'t go dirty, tailpipes & sparkplugs stay clean with no form of soot or carbon. Water temps just sits in the lowest position. No ping or Knock however slow you go with A/C on! So what must be happening inside to achineve this form of top gear performance all day and night! I am sure something else must be happening due to the grooves as nothing else has been touched or modified on my new car. Today i have covered close to 30000 kms in 11 months and the car feels like new. I can assure i aint dreaming,anybody driving my car can literally feel every ounce of torque flowing out of combustion as you step on the gas. give him an engine, he will better it for you with his groove design,pushrod or any rod - his design works.I can boldly back this statement.

Thomas Iype -ex. rallyist

Testimonials are fine, but we engineers like to see data from an impartial test facility.

Guys like me are convinced seeing Mr. Singh's technology work in our cars. Its for the engineers to take it to any impartial testing facility and convince themselves.

thomasiype

Three specific problems remain with pushrod engine or overhead valve (OHV) engine: Limited rpm; Difficulty in using crossflow cylinder heads in straight engine configurations; Limited valve flexibility .

Three specific problems remain with pushrod engine or overhead valve (OHV) engine: Limited rpm; Difficulty in using crossflow cylinder heads in straight engine configurations; Limited valve flexibility .

This is exactly why the Groove Heads are so quick to point out the benefits. There are limitations to pushrods and a development like Singh's Groove substantially helps. Limited rpm: with the Groove more power comes from low rpm.

Crossflow heads: increased turbulence from Groove improves this issue

Valve flexibility: Grooves are easy to change from head to head in order that new configurations can be tested.

This isn't fantasy football, these engines exist today in massive quantities, spewing inefficiently burned gasses and burning up more fuel for mile than necessary.

Auto Prophets should be able to foretell when a barefoot inventor will get some cash and a dyno, I'll forward the message personally :)

Seriously, why do all good ideas have to come from the lab? These whitecoats take their engines out on the test track before putting them in the showroom. This really warrants scrutiny and I reckon Somender would say "Bring it on."

Good ideas do not have to come from a lab, but they have to be proven in one. Otherwise, they are not science, but rather religion.

The Somender Signh modification mentioned earlier has been duplicated and confirmed here: http://mpgresearch.com/viewtopic.php?t=160&start=75&postdays=0&postorder=asc&highlight=

Keep the pushrod motors coming from GM. I have a 03 Buick Regal GSX (SLP Package) that is incredibly fast. 290 HP / 317 LB/ft torque (flywheel) from a GM 3800 Series II Supercharged V6 is impressive, and guess what, I still get about 20-22MPG combined driving. I'll never buy anything but a GM with a pushrod engine! Torque is for adults, horsepower is for the teenagers drooling over the Honda that needs to get up to 8000 RPM to make it's horsepower.

Really interessting. Never thought about before. I'll look for some more info!

The only reason I see you need a OHC, is in Formula One where the 2.4 L V-8 engine revs at 20,000 rpm and no pushrod can survive that much abuse (at the current engineered level), but it makes 750- 800 hp. A 5.8 L V-8 in Nascar revs at close to 9500 rpm and makes 850-950 hp. If you look at some of the high RPM races like Atlanta, Texas, and Lowe's some teams blow the engines at that rpm. Bottomline there is an advantage to OHV, and to OHC engines but I am sure if the boys at GM put their minds to it they could make a OHV rev at 20,000 rpm and make 1,900 hp and it could survive that abuse. It is just a matter of Engineering you parts to survive the vibration factor in a V-8 which continues to worsen through out the rev band but fixing it could come through counter balancing the crankshaft and adding/ subtracting weight to areas that need more/ less weigh.

Well, I have both worlds. I have a 94 honda accord, with 2.2l vtec, and a '02 monte carlo with a 3.8l pushrod v6. the monte is a tad faster, with 55 more HP, and lots more torque. With the much newer electronics, it gets very close to the mileage of my 2.2, but I do hit 5000 rpm many times a day, and 6200 (redline) about once a day. 145,000 miles, still no blue smoke. It seems the GM did a great job with the old pushrod motor. My G/F drives the Monte, and I drive the Accord. I love to drive it it suits my style, and the Monte suits her.

No complaints about the 3.4 liter pushrod V6 in my Montana aside from power. Anyway of wringig a little more out of that engine? Loaded with 3 kids and a dog it's straining.

push rod.. less moving parts, less to go wrong. nothing bad about older technology. the new Z06 vette runs to 7K .. even toyota is using a push rod for their race teams for the truck series. OHC and DOHC's motors are great designs, they offer efficiencies for their applications, usually lighter vehicles and higher rpms. but running a larger displacement motor in a heavier car. push rods have their point. A friend of mine in his old tech SBC has 300+ ft lbs of torque at anywhere from 2-2400 rpm..

one isnt better than the other. they are both one way to achieve a goal.

heck rotaries dont even have cam lol :)

bernard

Some of you may be surprised that the japanese used to make pushrod engines in their daily driver cars. I own a Toyota and Datsun both with a 30 year old pushrod engine and still gives good fuel economy as a modern engine. runs good too. Both are only 1.2 liters

pushrods are better, the only reason european and asian manufacturers concentrate on DOHC is the european and asian displacement taxes.

Of course, if NASCAR allowed DOHCs and more than two valves per cylinder, the teams would switch to OHCs virtually overnight.

And if the NHRA didn't ban DOHC and more than two valves per cylinder in its top professional classes (TF/FC/Pro Stock), OHV 2V engines would be obsolete there, too.

Forty-five years of overly restrictive rules packages have kept pushrods alive in the hearts of American hot rodders.

It it true that OHV engines can be externally smaller for a given displacement. However, one block-mounted camshaft simply cannot achieve as much "area under the curve" as a properly-engineered, modern DOHC with variable cam phasing and variable valve timing.

If any OEM built a 7.0 liter DOHC 4V engine with cylinder deactivation and VTEC-style cam timing, the debate would mostly be over.

I would think no matter what horsepower you make torque will get you through the horsepower faster, when you have the small high-rpm engines it takes longer to use all of the horsepower its making due to there lack of torque to upll threw the rpms. This is true for two cars that are the same hp and same waight but one is making 40 percent more torque it is faster because it pulls harder.

There is a reason the corvetter is ohv. A ferrari F430 has a smaller displacement dohc engine yet the car weighs the same, the engine technology costs more, it produces relatively the same horsepower with 3/4 the torque, and the cars have the same 1/4 mile time. Guess what happens after the 1/4 mile? The corvette blows it away. Meanwhile the corvette is getting 18 mpg city while the ferrari gets 12! Now if GM could only find a way to get all that massive power to the wheels without them spinning so it could actually be used...

I don't think this "Auto Prophet" knows what he's talking about here. BMW Valvetronic engines do not use cylinder deactivation, they use a very cool continuously variable lift system to operate in place of the throttle valve. This reduces pumping loss considerably and improves power output and fuel economy by up to 13%(!). He talks about how complex cylinder deactivation is in an OHC engine yet praises this Rube Goldberg pushrod contraption for its simplicity when it easily has more moving parts than a 300 hp DOHC V6. Then because of its V angle it probably wouldn't even be as smooth as a V6 and probably wouldn't have that deep throaty V8 sound. On top of that it STILL has pushrods in the way of the intake ports! Why hasn't this engine gone into production? Because it's a laughable piece of engineering just like pretty much everything else GM comes up with. Just make a DOHC V6 and supercharge it GM, it will have a lower part count even with 4 valves / cylinder. Let the freaking pushrod engine die already, geez.

Simplicity of pushrod engine...thats laughable. A DOHC engine has no pushrod, effectively reducing number of parts. And whats this about sound and torque ? it has nothing to do with pushrod or overheadcam, its only about camshaft timing and cam profile along with number of valves.

With a variable camshaft timing you cam actually change the timing to make the most torque at any engine speed instead of being fixed at a single predeterminated sweetspot like older engines.

And pushrod adds reciprocating weight, the WORST weight you can have. Leave it to piston and valves only to reciprocate, and puts in rotary weight in the form of double overhead camshafts.

In the 50,60's I would have prefer a Citroen DS over any american muscle car :P (even if the DS was unreliable, underpowered and would make american mechanics heads SPLODE! thus hard to service)

We're in the 21st century and car don't fly yet, in the meantime I'm a techno-whore concerning engine design

THAT said:

very interesting article, IMHO pushrods are cachet and a bit folkloric, well americana is dear for many people (europeans included)!

But wimpy hi-rev sohc engine with an electric motor for low-end torque or a super good VW diesel engine... The pushrod inovations just seems pale!

GMC really have to get their R&D shit together, europeans and japanese shove at us VERY reliable engines with new pertinent technologies!

Speaking of hirev cams, ever eard of desmodronic

http://en.wikipedia.org/wiki/Desmodromic_valve :D

The Grove on the heads is a Joke.

Bangalore now have a working Dyno.

Bring your car down and I can prove it to you.

The trick is really quite simple.

Quality of Gas has improved. So when you get a head. Shave it. Cut a grove and claim the grove is doing it.

Even Money your head has been shaved.

In his own testing at ARI on a Dyno they found no gains. Something like 2-3% at one RPM point.

Thats absurd.

I have an Ignition that can decrease emmisions by 80% and increase power by 30%.

Snake oil ?

No we just doubled spark strenth and dialed in a better map than what comes on these old engines.

I know a thing or two about the Baleno. Drop me a line and Ill show you what real power and fuel efficiency is.

Measure your head if its not been shaved or re-worked except for the grove then that is impressive. But if its been shaved by even a few microns then its a joke.

The New Dyno is avalible at White Feild and is being Run by Leela.

Put your car on the dyno.

the "pushrod" wich many people have learned to love and other have learned to hate, is quite old of course but the design is so simple, that not much can go wrong, and it provides power at low rmps. i have owned two vehicles with GM's 3800 3.8litre V6 engine. and that engine lasts, i have put those engines to the test, and they both have not given me any real problems, i dont even remember having any leak, of any type, and one of those cars has been flooded above the hood until the engine shut off...twice....and twice the car has come back to life withouth need of a mechanic, and i am so confident of my pushrod that i am shure it can be flooded another two times and it will still start the next day...

Having been stranded twice by a snapped timing belt (yes, yes, I know)... I believe there's something to be said for a low-revving gear-driven cam.

I wish you would do a story on hp per lb of engine weight. Currenly building a money-no-object car where hp per lb is the sole criteria. Cannot beat the LS7 for any amount of money.

A year or two ago AMG built a clean sheet V8 with every available technology including compensation for the reduction in fuel specific gravity caused by lunar proximity. With the added weight of extra cams and astronomically complicated ancillary systems it produced:505 hp. The same as the lighter, simpler LS7. Engine weight was not given. Never seems to be.

I just obtained an antique truck which had bent a push rod due to a stuck valve from sitting for 5+ years. That event would likely have broken the camshaft on an OHC engine. A few dollars for a set of push rods, a hammer and a block of wood and some WD40 and that 42 year old engine is now running like a song. I hope push rods are here for a while longer. I have had many high mileage vehicles over the years, and definitely prefer the simplicity of push rods over having bearings in the heads.

Agreed. When something works and is efficient, you stick with it.

All those little silver sticks jumping up and down in your engine thousands of times a minute do a very respectable job.

Great Article,personally i prefer the old style push-rod engines.

When I was installing process control for the Gen 3 line at Romulus (that would be about 1995) the GM guys told me that sticking with the pushrod layout let the engine height be less, allowing lower hoodlines, and that alone was the rationale. Remember that engine designs are heavily influenced by the body designers, at least within GM!

I spent another dozen more years deeply enmeshed in GM Powertrain, and I never heard anything different. I doubt it had a lot to do with manufacturing technology - the entire plant was new machine tools. They could have built anything they wanted.

Can't fault the decision - the Gen 3 was mostly the old smallblock with a radically stronger bottom end, and there wasn't much wrong with that old engine. Yes, you can't use a pentroof chamber, but at the typical compression ratios and RPM of a utilitarian 350 cube V-8 it really doesn't mean much.

I can also mention that some of the later OHC attempts by GM didn't fare so well, so it was IMHO a good business decision to stay with tried and true design for their mainstay powerplant.

An old performance guy once told me that power is made in the heads. The more volumetric flow you get into the combustion chambers the better it runs. That is why OHV engines make better power per unit of displacement than flatheads and that is why 4V DOHC motors make more than OHV engines. Its not about the power the engine it can make but how much it can make per unit of displacement. Sure some of small four bangers you have to rev the piss out of them to make power, and yes OHC motors take more room (modern packaging is improving though). The big advantage of OHC cam engines however is the fact that they actually have less moving parts than pushrod engines, some overhead cam models basically will have the cams, bucket tappets and the valves. Also the cam directly actuates the valves instead of a cam, lifter, pushrod and rocker arm. They also have more advanced VVT setups allowing for a broader powerband, and many overhead cam engines like the new 5.0 Coyote engine have excellent torque. Anyways how much torque do you need in car, most RWD and FWD cars will spin uncontrollably on street tires with more than 230 ft/lbs at full throttle. A perfect performance car motor will have at least 250ft/lbs of torque, but power will be solely determined by revs. That is why the BMW M3 has such a wonderful powerplant, a 4.0L V-8 that is compact for a DOHC, 420hp and 295 FT-lbs of torque and it runs with the LS series guys all day.

Post a Comment